Unlocking Business Potential with Advanced Printing Solutions: Mastering Heat Shrink Tubing Label Maker Technologies in Electronics

In today’s competitive marketplace, businesses in the electronics industry are constantly seeking innovative ways to improve product branding, enhance safety, and streamline manufacturing processes. As a key component of this strategy, durable printing services have become vital, especially when it comes to labeling solutions that withstand environmental challenges. Among these, the heat shrink tubing label maker stands out as a game-changer, offering unmatched versatility and durability that meet the precise needs of electronics manufacturing and maintenance.

Why Effective Labeling Matters in the Electronics Industry

Effective labeling is not just about branding; it’s essential for product identification, safety compliance, and operational efficiency. In electronics, labels must endure extreme conditions such as high temperatures, chemical exposure, moisture, and physical wear. Incorporating high-quality printing methods directly impacts:

- Product safety: Clear, durable labels prevent errors during assembly and repairs.

- Regulatory compliance: Accurate labeling ensures adherence to industry standards and legal requirements.

- Brand reputation: Well-printed, professional labels reflect positively on your business quality.

- Operational efficiency: Quick identification reduces downtime and improves workflow management.

The Science and Benefits of Heat Shrink Tubing Labels

Heat shrink tubing labels are specialized labels designed to be applied over wires, cables, and components in electronic devices. They are fabricated from flexible, heat-sensitive materials that shrink tightly around the substrate when heat is applied. This innovative design confers many advantages:

Superior Durability and Resistance

Unlike conventional labels, heat shrink labels are highly resistant to abrasion, chemical exposure, UV radiation, and extreme temperatures. Their resilience ensures longevity, maintaining legibility over years of service in harsh environments.

Enhanced Security and Tamper-Evidence

Because these labels are integrated with the cable or component seamlessly, they are less prone to peeling or tampering, ensuring high security for sensitive equipment.

Streamlined Application Process

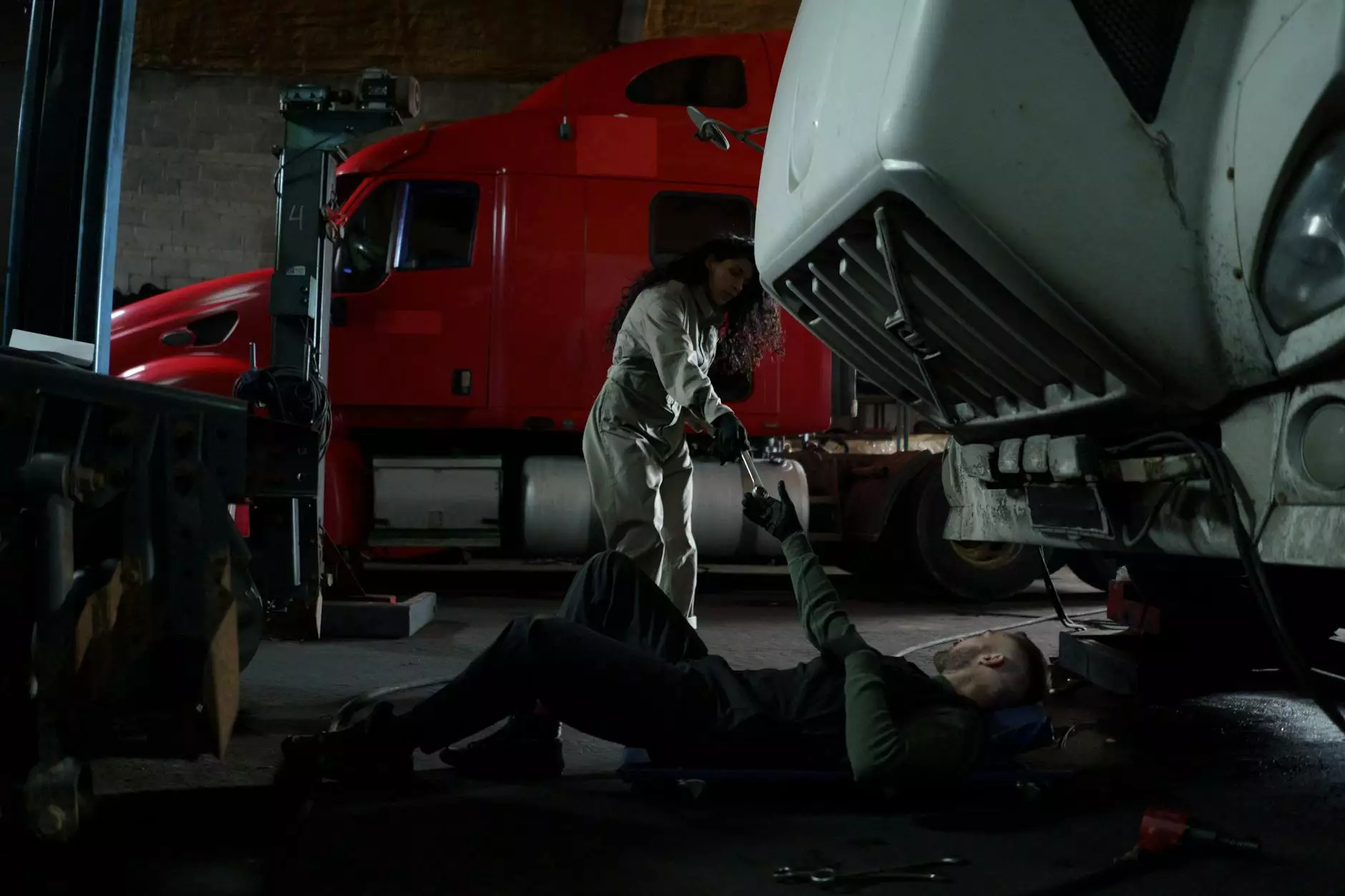

Using a heat shrink tubing label maker, technicians can quickly overlay labels on wires and parts, reducing labor time and minimizing errors during installation or repair.

How a Heat Shrink Tubing Label Maker Transforms Electronic Business Operations

Investing in a heat shrink tubing label maker can significantly impact the efficiency and professionalism of your electronics business. Here’s how:

1. Precision Customization and Design

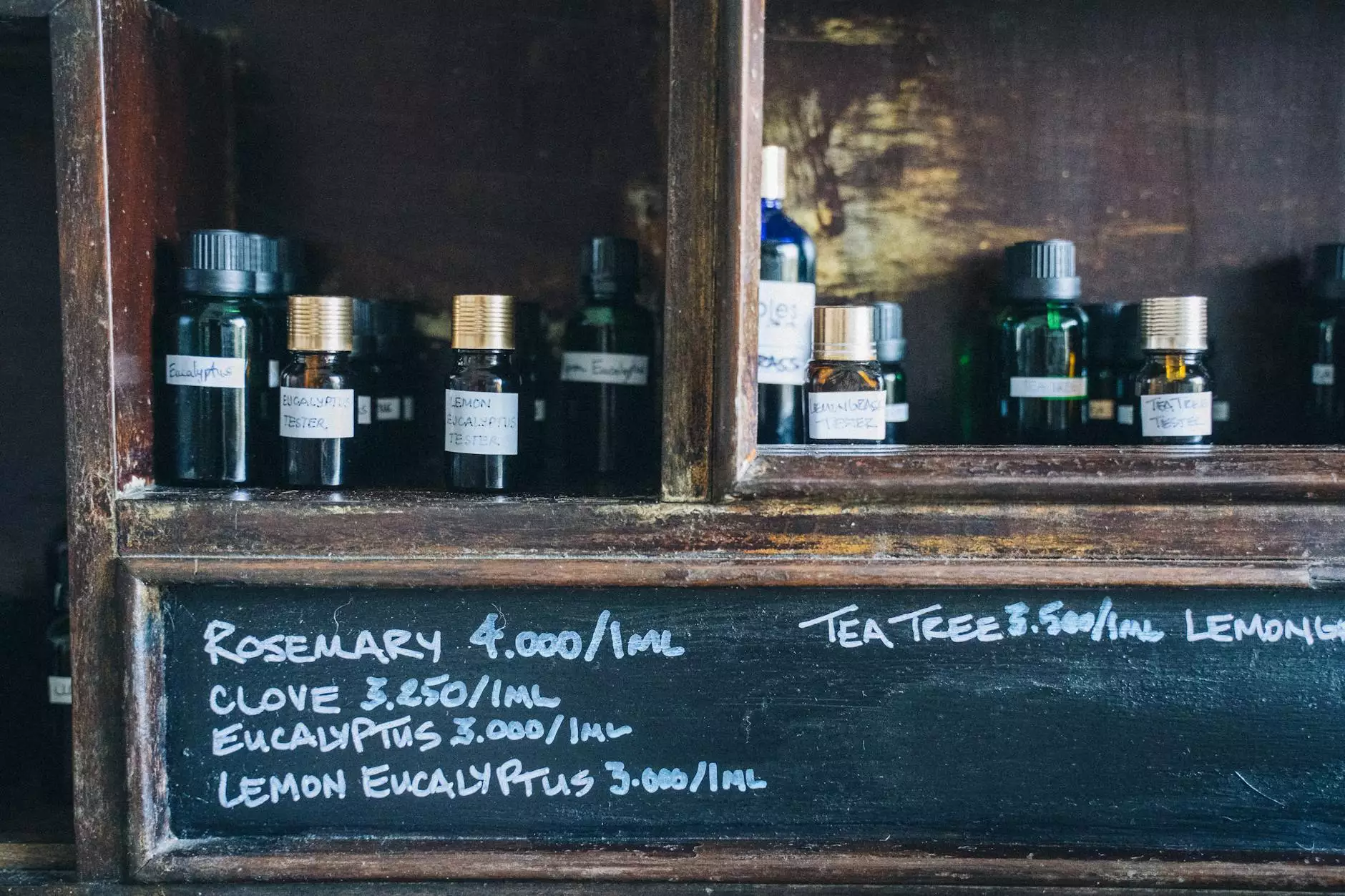

Modern label makers allow for detailed customization, including color-coding, barcodes, QR codes, and branding logos. This ensures your electronics components are not only labeled effectively but also integrated into your comprehensive asset management system.

2. Consistent Quality Output

Automated label makers deliver uniform labels with sharp printing, reducing errors associated with manual labeling methods. Consistent quality enhances brand trust and compliance adherence.

3. Cost-Effective Labeling Solutions

While the initial investment in a heat shrink tubing label maker may seem significant, the long-term savings in labor, material costs, and reduced product recalls far outweigh the upfront cost. Additionally, it cuts down on re-labeling or reworking electronic components.

4. Improved Safety and Regulatory Compliance

Accurate, durable labels ensure that all electronic components comply with safety standards and regulations such as UL, CE, RoHS, and others, helping prevent costly liabilities or recalls.

Choosing the Best Heat Shrink Tubing Label Maker for Your Business

When selecting a heat shrink tubing label maker, consider the following key features:

- Compatibility with Label Materials: Ensure it supports various heat shrink materials for different applications.

- High-Resolution Printing: Opt for models that deliver crisp, clear prints suitable for barcodes and small text.

- Ease of Use: User-friendly interfaces, touchscreen controls, and quick setup improve operational throughput.

- Speed and Efficiency: Fast printing and labeling cycles minimize downtime during high-volume production.

- Connectivity Options: Wi-Fi, USB, or Ethernet connections facilitate seamless integration into your existing workflows.

Integrating Printing Services into Your Electronic Business Workflow

Durafast Label, as a leading provider of printing services, offers comprehensive solutions tailored to the electronics sector. Integrating advanced printing technology, such as the heat shrink tubing label maker, into your workflow provides:

- Enhanced Product Traceability: Automatic printing and labeling streamline inventory management, ensuring each component is traceable throughout its lifecycle.

- Operational Flexibility: Custom labels can be produced on demand for prototypes, small batches, or large-scale production runs.

- Brand Consistency: High-quality printing maintains uniform branding across all products, enhancing professional appearance.

- Regulatory Adherence: Easily print compliance labels that meet industry standards for safety and environmental regulations.

Making Use of Advanced Printing Technologies in Modern Electronics Business

Advancements in printing tech, especially the heat shrink tubing label maker, enable electronics companies to adopt innovative practices:

- Automated Labeling: Reduce manual errors and increase throughput by automating the labeling process in assembly lines.

- Smart Label Integration: Incorporate QR codes or RFID compatible labels for IoT-enabled tracking and inventory management.

- Sustainability Initiatives: Use environmentally friendly, recyclable label materials supported by modern printing solutions.

- Custom Solutions: Work with suppliers to develop tailored labels that meet specific project or industry needs.

Conclusion: Elevate Your Electronics Business with Robust Labeling Solutions

In the dynamic landscape of electronics manufacturing and maintenance, durable, high-quality labeling is no longer optional—it is a critical aspect of ensuring product safety, brand integrity, and operational efficiency. The heat shrink tubing label maker stands out as one of the most effective tools to meet these demanding requirements, providing flexibility, durability, and precision that legacy methods cannot match.

By partnering with expert providers like Durafast Label, your business can leverage innovative printing solutions tailored to your specific needs. Whether you operate in assembly, repair, or distribution, investing in advanced labeling technology translates to better compliance, enhanced safety, and improved bottom-line results.

Embrace the future of electronic component labeling today to remain competitive and ensure the highest standards of quality and security in your products. Strategic integration of a heat shrink tubing label maker is not just an upgrade—it is a business revolution that positions your company for sustained success.